Spark

When the high voltage produced by the ignition system is applied between the center electrode and ground electrode of the spark plug, the insulation between the electrodes breaks down, current flows in the discharge phenomenon, and an electrical spark is generated.

This spark energy trigger ignition and combustion in the compressed air-fuel mixture.

This discharge is of extremely brief duration (about 1/1000 of a second) and is extraordinarily complex.

The role of the spark plug is to reliably generate a strong spark between the electrodes accurately at the specified time to create the trigger for combustion of the gas mixture.

Ignition

Ignition by electrical spark occurs because the fuel particles between the electrodes are activated by the spark to discharge, a chemical reaction (oxidation) is triggered, the heat of reaction is generated, and the flame core is formed. This heat activates the surrounding air-fuel mixture, eventually a flame core is formed that spreads the combustion to the surroundings itself.

However, if the quenching effect between the electrodes (the work of the electrodes absorbing the heat and extinguishing the flame) is greater than the flame core heat generation action, the flame core is extinguished and the combustion stops.

If the plug gap is wide, the flame core is larger and the quenching effect is smaller, so reliable ignition can be expected, but if the gap is too wide, a large discharge voltage becomes necessary, the limits of the coil performance are exceeded, and discharge becomes impossible.

WHAT IS A SPARK PLUGS HEAT RANGE?

The term heat range refers to the speed with which a plug can transfer heat from the combustion chamber to the engine head. Whether the plug is to be installed in a boat, lawnmower or race car, it has been found the optimum combustion chamber temperature for gasoline engines is between 500°C–850°C. Within that range it is cool enough to avoid pre-ignition and plug tip overheating (which can cause engine damage), while still hot enough to burn off combustion deposits that cause fouling.

The spark plug design determines its ability to remove heat from the combustion chamber. The primary method used to do this is by altering the internal length of the core nose. In addition, the alloy compositions in the electrodes can be changed. This means you may not be able to visually tell a difference between heat ranges.

*When a spark plug is referred to as a “cold plug”, it is one that transfers heat rapidly from the firing tip into the engine head, keeping the firing tip cooler.

*A “hot plug” has a much slower rate of heat transfer, which keeps the firing tip hotter.

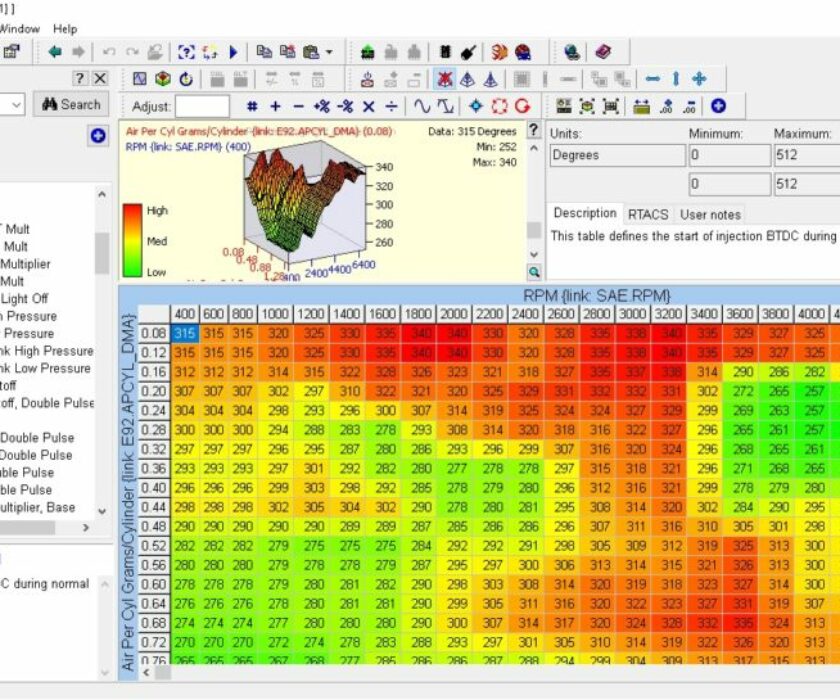

An unaltered engine will run within the optimum operating range straight from the manufacturer, but if you make modifications such as adding a turbo or supercharger, increasing compression, timing changes, use of alternate fuels, or sustained use of nitrous oxide, these can alter the plug tip temperature, necessitating a colder plug.

A good rule of thumb is, one heat range colder for every 75–100hp added.

In identical spark plug types, the difference from one full heat range to the next is the ability to remove 70°C to 100°C from the combustion chamber.

The heat range numbering system used by spark plug manufacturers is not universal.

For example, a 10 heat range in Champion is not the same as a 10 heat range in NGK nor the same in Autolite.

Some manufacturers numbering systems are opposite the other – for Champion, Autolite and Bosch, the higher the number, the hotter the plug. For NGK, Denso and Pulstar, the higher the number, the colder the plug.

It is not recommended that you make spark plug changes at the same time as another engine modification, such as injection, carburation or timing changes. Performing too many modifications or tune-ups at once will lead to misleading and inaccurate conclusions if any issues occur (an exception would be when the alternate plugs came as part of a single pre-calibrated upgrade kit).

When making spark plug heat range changes, it is better to err on the side of too cold a plug. Running too cold a plug can only cause it to foul out, whereas running too hot a plug can cause severe engine damage.

SPARK PLUG DIAGNOSIS

DIAGNOSTIC OF FAILURE

| Failure | Cause | Consequences | Fig. |

|---|---|---|---|

| Improperly adjusted ignition system | Spark advance (from a proper moment) | Pre – ignitions /Detonation burning | 2 |

| Spark delay (from a proper moment) | Excessive formation of combustion deposits | 1 | |

| Improper air/fuel ratio | Rich mixture | Excessive formation of combustion deposits | 1 |

| Lean mixture | Pre – ignitions /Detonation burning | 2 | |

| Low or no performance of the air filter | Dust penetration into the combustion area | Excessive deposits | 3 |

| Filter impassability | Excessive formation of combustion deposits | 1 | |

| Compression pressure | Low | Excessive formation of combustion deposits | 1 |

| Improperly selected spark plug | Too hot | Pre – ignitions Detonation burning | 2 |

| Too cold | Excessive formation of combustion deposits | 1 | |

| None | Perfect performance of the spark plug | 4 |

Spark plug is like a dipstick into your engine, which will let you see what is going on inside of the combustion chamber.

The two most destructive combustion events to the engine and the Spark Plug are: PRE-IGNITION and DETONATION. These terms are commonly misunderstood and confused with each other.

Detonation occurs after normal combustion (controlled burning) was initiated from a spark between spark plug electrodes. As the flame front propagate trough the combustion chamber, the pressure and heat on the remaining yet un-burnt mixture increases dramatically pass the point of fuel octane rating and any hot spot (most often hot side of the piston) will detonate (explode) the remaining yet un-burnt mixture. This event takes place in a split second and cause extreme pressure shock wave, which often pits the piston surface (looks sandblasted as it compresses less dense micro-portions of the aluminum alloy) and almost always breaks ceramic insulator on the spark plug. The damage to the spark plug is a result of the events and the high frequency shock wave. Please note that detonation is a different event than pre-ignition where the mixture is ignited by usually hot spot, glowing carbon deposit or overheated ground spark plug electrode, prior to the mixture ignition by spark form spark plug. Pre-ignition is far more destructive to the engine than detonation because maximum cylinder pressure is reached far before the piston reach the TDC (top dead center). Pre-ignition will destroy the engine, put hole trough the piston, or even blow it up. Detonation (can be also heard as engine knock or pinging) is not necessarily damaging to the engine if it is not prolonged and only very small amount of un-burnt mixture detonate. Modern engines in order to reach the maximum fuel economy run on the edge of pinging. They use knock sensors to “listen” for the pinging and retard the timing accordingly. However prolonged and severe detonation will hurt the engine and the spark plug, and is probably the most common cause of failure due to inconsistency of the octane rating of gasoline. Modern engines are equipped with a Knock Sensor which provides feed back to engine ECU/PCM to adjust engine ignition timing in order to prevent prolonged detonation. However engine knock sensor is often not working properly, or is purposely eliminated on some performance applications, which exposes engine and spark plug to damage from severe detonation. Spark plug is passive component with 3 basic functions. It have to: 1) stay cool enough to prevent pre-ignition 2) stay hot enough to burn off combustion deposits 3) provide spark to ignite A/F mixture. About the only time you can blame spark plug for a failure, is if too hot spark plug heat range is used and the spark plug ground electrode gets too hot and become a source of the pre-ignition.