Methanol Injection

A methanol injection system is a fully integrated system that injects liquid alcohol into the engines inlet system as commanded by a electronic controller. The system is comprised of a containment tank, a high pressure pump, steel braided lines and a point of injection. The system is then activated with a controller based upon numerous inputs.

First lets talk about why we would inject methanol into the engine. Methanol, being an alcohol, has what is referred to as a “high vaporization of heat”. This means that during its evaporation, it removes heat from the surrounding air. The benefit to this is that engines will make more power with cooler inlet charge temps, especially in a boosted application as compression air makes more heat!

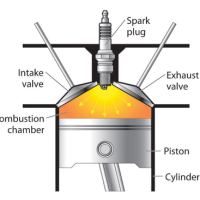

Methanol also has a octane rating of 111 (based on R+M/2) which compared to premium pump gas is 93. Higher octane fuels are referred to as “Knock Limited” fuels meaning they resist detonation better. With high octane the engine can then be calibrated with more optimized ignition spark timing which will lead to into a power increase as timing is closer to peak cylinder pressure.

Lastly…..methanol is a fuel source by itself. In application which there is not enough fuel system in the vehicle to support higher power (higher airflow), the methanol can make up for this short coming. This is something that has become more exposed in the newer Direct Injection vehicles where fuel system upgrades are more complicated and expensive.

The controller to active the injection is either based off MAF (Mass Air Flow) or by MAP (Manifold Absolute Pressure) inputs. The MAF based strategy is used on Positive Displacement type superchargers (Magnuson, Whipple). The MAP based strategy is used on Centrifugal superchargers (ProCharger, ECS, A&A). The reason for this is a PD blower can make a lot of MAP pressure (Boost) at low throttle angles yet not need the methanol to be injected. Using the MAF the controller will be able to identify larger air mass as the time to start injecting. I centrifigal blower makes boost very linear so this is better picked up by a MAP sensor.

Frequently Asked Questions

Do I use Methanol all the time?

No. The Methanol System is ONLY active under load (demand). If you start your car and drive around all day and never get into boost you will not use any methanol. Consequently if you drive the car very hard you will use more meth.

How do I know the Methanol System is working?

The systems all utilize a small LED light which we strategically locate in sight. When the system is actively working the LED will light up green.

Where does the meth get filled?

Often the windshield washer reservoir is used to hold the methanol. Customers looking to still utilize the factory washer tank can opt for a remote mounted tank.

Where would I expect a gain from meth injection?

As noted, methanol is a high load supplement upgrade. Mainly used in boosted applications. Because we have improved cooling, high octane and a fuel source we can run high boost pressures and further optimize the ignition spark timing to make more power. The power gains will be yielded under power and not during lighter driving demands

What happens if I run out of meth and drive the car?

Since the meth system is used to extract performance increases; much of this comes from increased boosted, more spark timing and also as a fuel source. If the meth is not working your engine will not be performing as intended and you can hurt the engine! It is the responsibility of you the customer to sense when your out of meth and the system is not working!